Materials can be delivered via the following media:

– CD, DVD

– e-mail (files no larger than 10 MB)

– FTP server – production files should be placed on the print shop’s server in a folder named after the company/institution.

Please confirm each file upload to the FTP server by e-mail.

Files sent to the FTP server can be protected from third-party access only if they are sent to an individual FTP account (we can create such an account upon client request). We cannot guarantee such protection when using a shared FTP account.

We work with closed projects in PDF format versions 1.4 – 1.6 (Acrobat 5–7)

All files should be named according to the following pattern:

job name_ issue number_page number.pdf

In case of corrections:

job name_ issue number_page number_correction.pdf

For different language versions:

PL_job name_ issue number_page number.pdf

ENG_job name_ issue number_page number.pdf

DE_job name_ issue number_page number.pdf

File Approval

To finalize the acceptance of materials for printing, we provide a preview of the files after ripping in low resolution (JPEG 200 dpi, low quality).

File Corrections

If the entire job is saved as a single PDF file, all corrections should also be submitted as a single revised file – without individual page replacements.

Resolution

The resolution of images included in the files should not be lower than 300 dpi. Sending graphics with lower resolution means accepting reduced image quality. Image resolution should also not exceed 400–500 dpi due to file size optimization.

Profiles

Graphic elements must not contain embedded profiles (no embedded ICC profiles).

Format

Files must be centered on the page. The trim box size must match the net page format.

Color space, Spot colors

All graphic elements must be in CMYK color space. Do not send images in other color spaces like RGB or Lab. All spot colors (e.g., Pantone®) must be converted to CMYK.

Spot colors may only be used after consultation with the printer and must be included in the files.

Maximum ink coverage

Maximum ink coverage (TAC or TIL) should not exceed 320% for coated papers and 280% for uncoated papers.

For complex or demanding jobs, it is recommended that the client include a proof for each page. Proofs should be made from files approved by the client for printing. Each proof must contain a control strip and certification. Without certification, the proof cannot be used as a reference material.

If the client approves the print, the certified and signed sheet becomes the reference for the press operator. Prints from previous editions do not constitute a reference proof — they can only serve as a point of reference. Using such a reference may result in different color reproduction due to lack of information on material preparation, the printing process, and materials used in the previous print shop. If the client does not supply proofs and is not present during sheet approval at the press, printing is done using the print shop’s standard optical density settings, and the print shop takes no responsibility for potential color differences.

COLOR – bleed area of 3 mm on each side

COLOR – trim line (net graphic size)

COLOR – safe zone: no text or important graphic elements within 3 mm of the final trim size

Each page must have bleeds of at least 3 mm on all sides.

Important text or graphic elements should be placed at least 5 mm from the trim line. Trim marks should be 3–5 mm outside the net format. Pages should not include additional marks or color bars. Including publication date and page number in the margin will help identify the file in the absence of folio (page numbers).

For print aesthetics and binding fold tolerance, avoid placing a single line of small-sized text across adjacent columns. Splitting text between columns in the middle of a word is not allowed.

Minimum font size for single-color printed text:

– for single-element fonts: 6 pt

– for two-element fonts: 7 pt

Minimum font size for multicolor or reversed (knockout) printing:

– for single-element fonts: 8 pt

– for two-element fonts: 10 pt

The minimum acceptable line thickness is 0.2 pt. Lines in knockout or printed in more than one color must be at least 0.75 pt thick.

To avoid misregistration, use trapping — a slight overlapping of colors. The recommended trap size is 0.05 mm (0.144 pt). For reversed text on a black background using 4-color CMYK, negative traps of 0.17 mm (0.5 pt) are recommended.

Black text sized 24 pt or smaller on a colored background must be set to overprint. Overprint must not be used for objects in any color other than black.

When assembling covers for perfect binding, it is necessary to include a designated color area for glue on the inside spine, as well as side glue margins of 6 mm width, according to the illustration below.

1. Missing embedded fonts / fonts not converted to outlines

2. Low-resolution images

3. Bleed too small or missing

4. Files containing elements or images in RGB or other than CMYK and PANTONE

5. White elements or text set to overprint

6. Lines that are too thin

7. Black text or elements not set to overprint

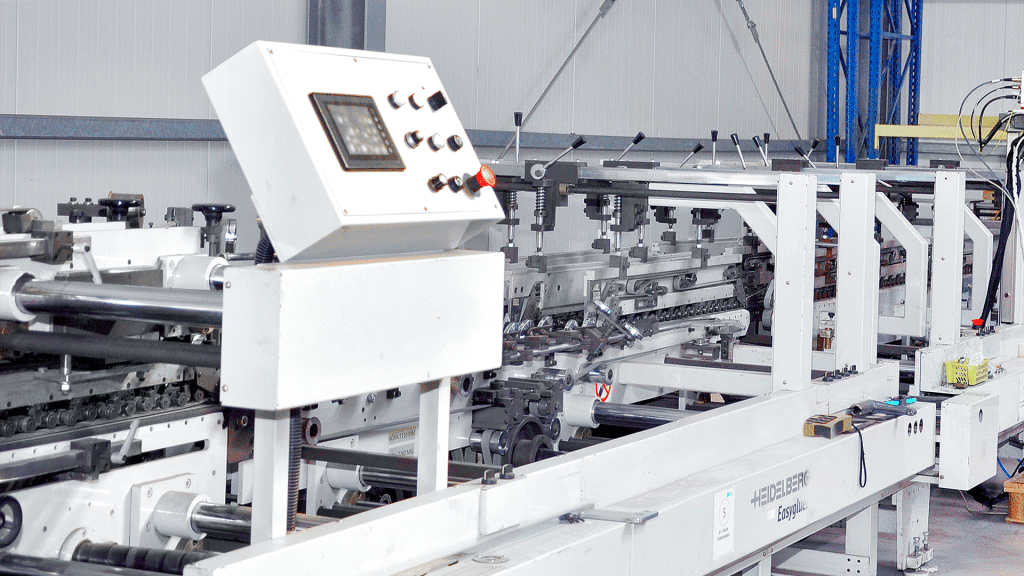

Perfect Binding (Softcover)

including flap covers:

Minimum format

Spine length: 120 mm

Book width (base): 100 mm

Spine thickness: 3 mm

Maximum format

Spine length: 380 mm

Book width (base): 320 mm

Spine thickness: 50 mm

Saddle Stitching (Wire-stitched):

Minimum format

Spine length: 110 mm

Book width (base): 100 mm

Maximum format

Spine length: 365 mm

Book width: 305 mm